Professional slip ring manufacturer

Electric Slip Ring

”The latest newsThe hollow slip ring is called the through hole type slip ring, which is a porous structure. It has a wide range of applications. It is mainly installed on the rotating shaft device. The rotary joint adopts through hole slip ring, which is required to transmit signals in fixed and unfixed structures.

How to select the material of the slip ring? Application field of the pneumatic electric slip ring

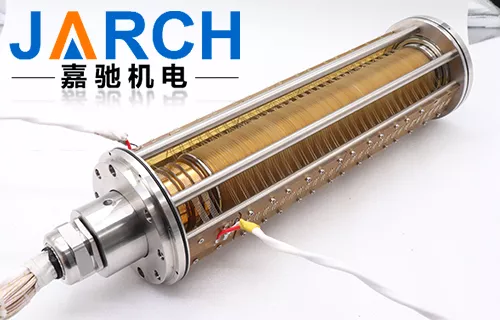

The gas electric slip ring is composed of gas slip ring and electric slip ring, which saves a lot of space compared with the traditional mode. Since its establishment in 2006, JARCH Electromechanical Co., Ltd. has been committed to the research, development and production of conductive slip rings. It has paid a lot of energy and made many breakthroughs. The independently researched, developed and produced gas electricity integrated slip rings are widely used in various fields.

We all know that conductive slip rings are electrical products that can rotate and transmit various media. We have also encountered many problems when using conductive slip rings. One is that the signal transmitted by the conductive slip ring is always unstable, etc. In fact, these problems are small problems we encountered when using the conductive slip ring. Today, the editor of Jiachi conductive slip ring will tell you about the conductive slip ring. What should I do if the transmitted signal is unstable and is always disturbed.

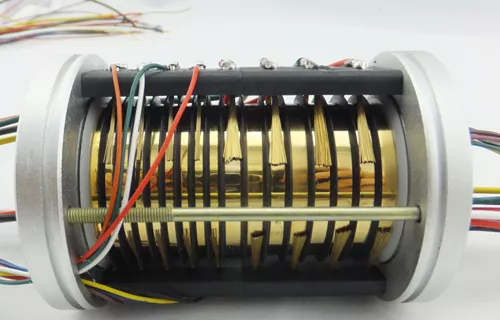

With the development of the times, the progress of science and technology, automated equipment has become the backbone of the world's manufacturing industry. As an important electrical component in automation equipment, the conductive slip ring has also developed by leaps and bounds with the advancement of science and technology, and the traditional conductive slip ring has also Known as the collector ring, traditional carbon brushes and copper rings are used as contact materials, and the rotating copper ring is rubbed against the carbon brush to ensure the rotational transmission of the equipment. Because the contact material of this traditional collector ring is a common carbon brush, the medium it transmits is limited to common current and simple control signals. However, with the advancement of technology, automation equipment has entered electrification and networking, and modern automatic equipment is often controlled through the network.

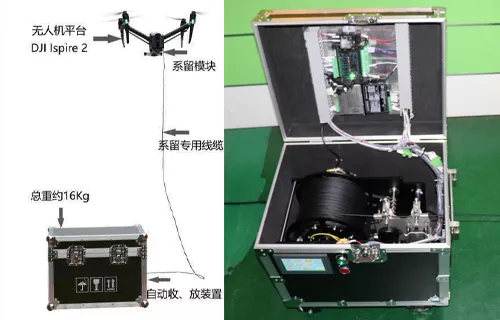

Tethered UAV, also known as tethered UAV, is a special form of multi-rotor UAV. It uses ground power transmitted through tethered cables as a power source instead of traditional lithium batteries. It is characterized by the ability to hover in the air for a long time. The tethered drone is composed of a ground high-voltage DC voltage stabilization system, a pay-off device, a synchronous reel, a mooring cable, an air voltage stabilization module and a backup battery. The high-voltage DC voltage stabilization system And the synchronous reel is installed on the reel, and the tethered cable is connected with the voltage regulator module and the backup battery.

Simply put, the function of the coating machine is to apply glue and other media on the surface of films, textiles, sponges and other products, generally including unwinding, gluing, drying, winding, and roll changing. Coating machines play a key role in shoe accessories, sponge products, electronics industry, textiles and other industries. Manual gluing is slow and inefficient, and cannot expand production capacity. In addition, the stimulating properties of media such as glue can adversely affect the human body. The coating machine will automatically complete the above process and strictly uniform according to the set process.

news

- New HD High Frequency Video Combination Slip Ring Solution!!!Why does High-end Equipment Use Fiber Optic Slip Rings Instead of Standard Slip Rings? How Wide the Application Range of Mercury Slip Rings,Do You Know it?

- How to solve the problem of smoke when the conductive slip ring is in use?---The importance of using fiber brush technology for conductive slip ring,and do you know the Wind power slip ring?

- How to Choose the Model of the Slip Ring You Need? The Installation Method of the Rotating Slip Ring--Shaft or Flange?

- The difference between the old carbon brush slip ring and the new brush slip ring, what are the media transmitted by the slip ring?

- How to use disc conductive slip rings and the advantages and characteristics of mercury slip rings

- How does the slip ring realize the simultaneous transmission of multiple media? How does a slip ring work?

- Is the life of the conductive slip ring long? Why is the service life of the mercury slip ring not long?

- Is it true that miniature cap-type slip rings are widely used in anchor fish equipment? How to choose a through hole slip ring correctly?